Service Hotline

00864006988696

Negotiable

¥0.05

Negotiable

Negotiable

Negotiable

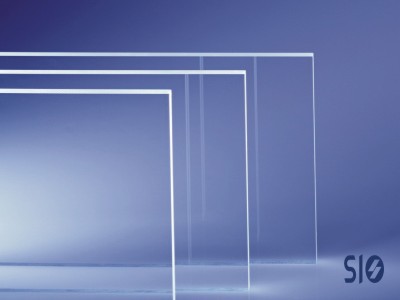

Borosilicate 3.3 float glass

High borosilicate glass (also known as hard glass) is a kind of glass melted by heating inside the glass at high temperature. It is processed by advanced production technology. Its linear thermal expansion coefficient is (3.3 s 0.1)x 10-6/K. It is also called "borosilicate glass 3.3". It is a kind of special glass material with low expansion rate, high temperature resistance, high strength, high hardness, high transmittance and high chemical stability. Because of its excellent performance, it is widely used in solar energy, chemical industry, pharmaceutical packaging, electric light source, handicrafts and other industries. Its good performance has been widely recognized by all walks of life in the world, especially in the field of solar energy, which has been widely promoted in developed countries such as Germany and the United States.

Product characteristics

Good High Temperature Resistance

Excellent heat shock resistance

Excellent transmittance for a variety of optical applications

Light weight and high strength

Applications:

· Semiconductor, Microelectronics, Sensors (Optical Communication, Silicon Wafer Bonding, CCD/CMOS, MEMS, IC Packaging, Wafer, Substrate and Optical Components)

· Medical technology and biotechnology (microarray chip, slide, DNA array, microscope slide, enzyme plate, X-ray cover plate, culture vessel)

· Environmental Engineering, Chemical Industry (Corrosion Resistant Lining and Observing Mirror of Reactor and Fluid System)

· Optics (Digital Projector Mirror, Optical Instrument, Telescope Lens, Ultraviolet Mirror, namely, UV Mirror, Filter, Cold Mirror, Reflector Cover, Chromatic Wheel, Chromatic Separation Filter, Folding Mirror, DWDM Filter)

· Lighting (stage lights, spotlights, spotlights, and protective panels for high-power floodlights)

And home appliances (microwave oven, oven, fryer pyrolysis oven lamp cover, protective cover, household oven tray, industrial washing machine)

· Photovoltaic System (Solar Cell Substrate)

technical parameter

1. Out-of-factory dimensions (mm): 1150 x 850; 1200 x 600; 1150 x 1700

(Other sizes can be manufactured as required)

2. Thickness (mm): 2.0-15

3. Density (g/3): 2.23 +0.02 (at 25 C)

4. Expansion coefficient (a):3.3+0.1*10-6 (20-300 C)

5. Softening Point ():820+10

6. Temperature difference property of the same sheet (?) > 100 > 300 (enhanced type)

7. Heat Shock Resistance (): > 125 > 300 (Enhanced)

8. Maximum operating temperature (?): > 450

9. Visible light transmittance: 92% (thickness < 4mm) and 91% (thickness < 5mm)

Chemical properties

1. Water resistance: ISO719/DIN12111 ISO720 HGA1

2. Acid resistance: ISO1776/DIN12116 1

3. alkali resistance: ISO695/DIN52322 A2

Electrical properties

1. Resistivity LG p: 8.0_ * cm at 250 (?)

2. Dielectric loss Tan (1 MW 20 C): 38 *10-4

3. Dielectric constant: e = 4.7

* The thickness of sheet metal is measured by laser measuring instrument in the production process. Other items can be provided according to customer's requirements.

Calibration size, thickness and tolerance.

Prices are for reference only. Detailed prices are welcome to inquire by letter or telephone.

If you have any questions before purchasing, please contact us.